Control Top T.VIS® A-15

Development has focussed on the requirements and necessities of our customers from the fluid-processing industry. In addition to safe control and monitoring of all functions of the process valves in breweries, dairies, plants for manufacturing fruit juices as well as pharmaceuticals, the T.VIS® A-15 offers significant advantages that are directly reflected in lower total cost of ownership.

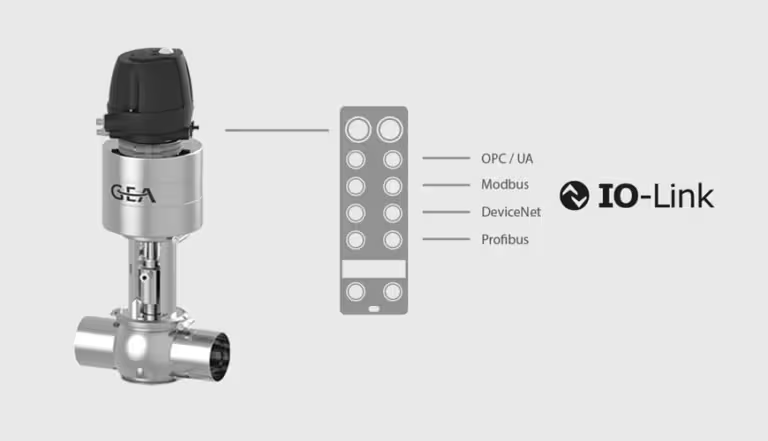

- IO-Link

- Quick, automatic initialization

- Tamper-proof setting of tolerances

- Reduced energy consumption

- Reduction in operating costs

- Valve status display by LED

- Filter protects solenoid valves

- High-quality pneumatic fittings

- Exchangeable compressed air connection

- Supply and exhaust air throttles can be fitted

- Logic NOT-element

- LEFF® function

- Semi-automatic setup

- Standard protection class IP66

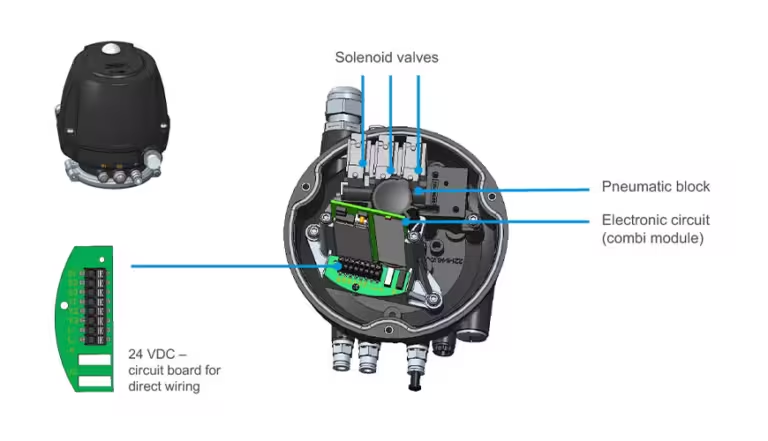

The T.VIS® A-15 is equipped with a precise path measuring system for detecting its position. The necessary wiring for control and feedback is performed, depending on the requirements, via the M12 plug connections accessible from the outside or through direct wiring and cable glands. The control top can be opened for this.

Operation and configuration of the T.VIS® A-15 takes place either by the two push buttons on the cap or, with the cap removed, via the buttons below. The push buttons are secured electronically against inadvertent or incorrect operation, while in operating mode.

A replaceable filter, in the supply air connection, protects the solenoid valves.

Path measuring system – the valve position is registered by means of a highly modern path measuring system.

Automatic – following unlocking, simply pressing the two buttons on the cap on the T.VIS® A-15 starts the initialization process which runs fully automatically. There is no need to open the control top for this purpose, resulting in particularly quick, easy and safe commissioning of the control top (on average < 1 minute).

Immediately following the set-up, it is possible to set the open/close position tolerances and signal attenuation in the parameter menu.

Activation of the main stroke which may be required in VARIVENT® and ECOVENT® valves with open non-actuated position for valve maintenance is performed using the service mode which can be activated by the buttons. At the same time, all feedbacks are stopped (warning to the system control).

Furthermore, input signals from the control room are not implemented by the T.VIS®, in order to protect the employee.

T.VIS® A-15. Please refer to the catalog for more information.

Technical Data of the Standard Version

| Position detection | Path measuring system | |

| Housing material | PA12/L | |

| Ambient temperature

|

-20 to +55 °C | |

| Air supply | Pressure range | 2 to 8 bar |

| Air supply | Standard | acc. to ISO 8573-1:2010 |

| Air supply

|

Solid content | Quality class 6 |

| Air supply | Water content | Quality class 4 |

| Air supply | Oil content | Quality class 3 |

| Dimensions of air connections | Metric 6/4 mm, inch 6.35/4.31 mm (¼”) | |

| Protection class | IP66 (powerful water jet) | |

| Sound pressure level via exhaust air throttle | Max. 72 dB | |

| Visualization | LED (green, yellow, red) | |

| Certificates | optional: UL/CSA, only for indoor use and only with interface type A, B, D, and I | |

| Certificates | optional: UL 121201 – Nonincendive Electrical Equipment for Use in Class I and II, Division 2 and Clas III, Divisions 1 and Hazardous (Classified) Locations | |

| CSA C22.2 No. 213-17 | Nonincendive electrical equipment for use in Class I and II, Division 2 and Class III, Divisions 1 and 2 hazardous |

”*” anger obligatoriska fält

Vill du hitta kontaktuppgifter till en specifik person eller kontor?

Här hittar du alla våra kontaktuppgifter.