Control Top T.VIS® M-20

The control top GEA T.VIS® M-20 offers the entire range of modern control functions required in the majority of application points, plus additional advantages in terms of automated valve commissioning and efficient equipment management.

The ideal solution for the majority of application points with a maximum requirement of two feedbacks and up to three solenoid valves.

For all GEA Butterfly valves

For all GEA VARIVENT® Valves *

For all GEA ASEPTOMAG® and GEA D-tec® Valves *

(* except with monitored seat lifting)

- Proven housing technology

- The highest protection class as standard

- High vibration and shock resistance

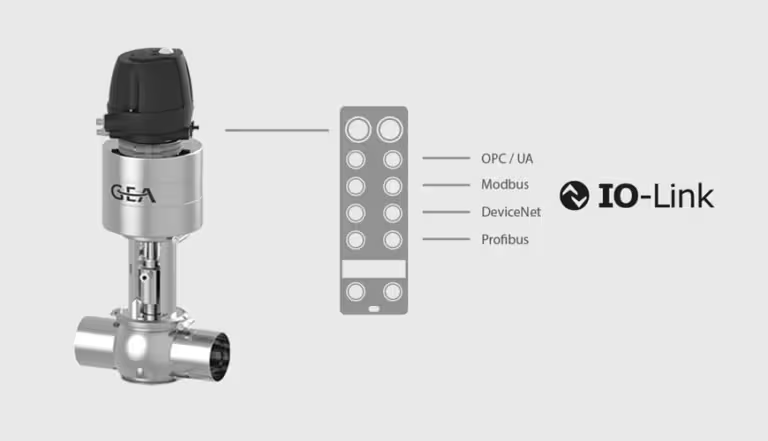

- Individual connection technology

- Self-learning initialization

- Extremely easy commissioning

- Parameters can be preset

- Standardized T.VIS® visualization with diagnostic function

The T.VIS® M-20 is equipped with reliable and robust control electronics, containing the proven path measurement system of the T.VIS® A-15 as an on-board version. The cable connection to the central control level is implemented by the customer, either via externally accessible M12 plugs or via direct wiring to internal spring-loaded terminals, depending on the requirements. Parameters can be preset via DIP switches so that the actual commissioning no longer requires any further operation or configuration. Using an internal reset button, the electronics can be reset to delivery status after a valve service, so that a new self-learning process takes place automatically when the system is restarted. The supply air connection is equipped with a replaceable filter to protect the built-in solenoid valves.

Parameters such as tolerances, color switching or air support can be set using integrated DIP switches. The actual initialization process runs automatically. The procedure only requires closed connections between the control top and the air supply and electrical equipment. No other tools are necessary.

Optionally, a logic NOT-function can be integrated into the control top without additional control effort. This provides automatic air support for the spring chamber to increase the closing force of the valve.

| Item | ||

| Position detection | Sensors | |

| Housing material | PA12/L | |

| Ambient temperature | -20 to +55 °C | |

| Air supply | Pressure range | 2 to 8 bar |

| Air supply | Standard | acc. to ISO 8573-1:2010 |

| Air supply | Solid content | Quality class 6 |

| Air supply | Water content | Quality class 4 |

| Air supply | Oil content | Quality class 3 |

| Dimensions of air connections | Metric 6/4 mm, inch 6.35/4.31 mm (¼”) | |

| Protection class | IP69k | |

| Sound pressure level via exhaust air throttle | Max. 72 dB | |

| Visualization | LED (green, yellow, red) |

”*” anger obligatoriska fält

Vill du hitta kontaktuppgifter till en specifik person eller kontor?

Här hittar du alla våra kontaktuppgifter.