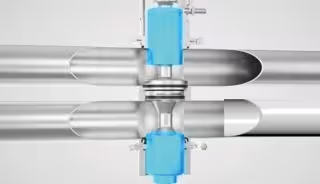

VARIVENT® Mixproof valve type MX

We are at the beginning of a new era in which successful companies and brands define themselves through their status as pioneers for maximum safety of their products – protecting consumers and their own workforce.

The new GEA VARIVENT® Mixproof valve type MX offers innovative technologies as essential elements of future-oriented safety concepts. It offers a measure of product safety that goes far beyond previous requirements.

The optimized physical design of the leakage cavity creates a negative pressure. Should a seal fail, the product is removed by vacuum and guided to the periphery without the risk of contamination (Venturi effect).

Thanks to specially shaped balancers in both pipelines, the valve remains stable in the closed position even in the event of water hammer and, on the other hand, retains its full ability to act even in the case of hydraulic lock or thermal expansion of the medium.

Up to four feedbacks can be applied to ensure exact control and documentation of the valve status at all times.

The uncompromising hygienic design of all components ensures maximum efficiency in valve cleaning, now enhanced by automatic external cleaning of the lower balancer when the lower valve seat is lifted.

The specially improved valve technology of the new GEA VARIVENT® Mixproof valve type MX fulfills the world’s strictest design specifications for hygienic valves (3A, EHEDG).

Closed actuator housings, thoroughly protected by specially designed piston seals – designed to be maintenance-free. The robust design supports uninterrupted process operation and saves valuable time and operating costs.

| Material in contact with the product | 1.4404 (AISI 316L) |

| Material not in contact with the product | 1.4301 ( AISI 304) |

| Seal material in contact with the product | EPDM, FKM, HNBR |

| Ambient temperature | 0 to 45 °C |

| Air supply pressure | 6 bar (87 psi) |

| Product pressure | 10 bar (145 psi) |

| Water hammer safety | 50 bar |

| Surface in contact with the product | Ra ≤ 0.8 μm |

| External housing surface | Matte blasted |

| Control and feedback system | T.VIS® M-20, T.VIS® A-15 |

| Actuator type | Pneumatic actuator air/spring |

| Connection fittings | Welding end |

| Identification | Adhesive ID tag |

| Valve seat version | Welded seat ring |

| Certificates | CE, EHEDG, FDA |

"*" indicates required fields

Vill du hitta kontaktuppgifter till en specifik person eller kontor?

Här hittar du alla våra kontaktuppgifter.